Toothbrush

Lattice and Topology Optimization for Additive Manufacturing Fall 2018

Initial Design

A simple toothbrush CAD design was modeled in Onshape.

Different views of the model show off the different features

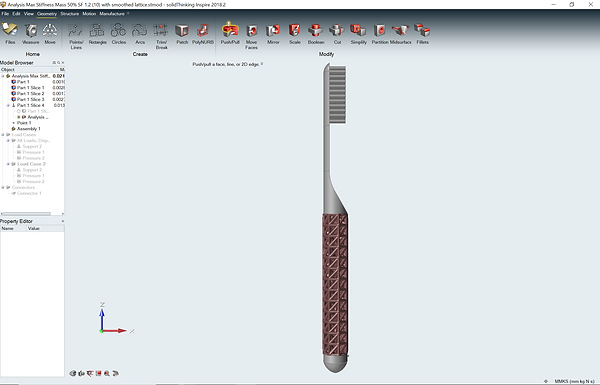

Lattice Optimization

The settings used in the optimization:

-

Type: Lattice

-

Objective: Maximum Stiffness

-

Mass Targets: 50% total design space reduction

-

Target Length: 7.5mm

-

Minimum Diameter: 2mm

-

Maximum Diameter: 3mm

-

Fill with: 100% Lattice

-

Frequency constraints: None

-

Speed/Accuracy: Faster

-

Contacts: Sliding Only

-

Gravity: No

-

Safety Factor of 1.2

-

Blended Contours

-

Smooth Lattice

-

Material: Plastic (ABS)

Altair Inspire was used to lattice the handle.

Three different analyses shown: Tension/Compression, Displacement, and von Mises Stress

The initial and final positions are shown by the grey outline.

The Load Case is shown with the red arrows:

-

Pressure at top section of 0.015MPa

-

Pressure at middle section of 0.015MPa

-

Support on lowest section

Topology Optimization

Generative design was used for this iteration.

-A design space was created in Onshape that retained the toothbrush bristles and general round handle with a flat bottom.

-The space was cut and partitioned in Altair Inspire to account for the pressure of each finger on the handle and the pressure from the teeth during brushing.

-

.015MPa on the toothbrush head

-

.015MPa from the index finger

-

.005MPa from the thumb

-

.001MPa from the middle finger

-

.001MPa from the ring finger

-

.003MPa from the pinky finger

-

Support on the flat bottom

-A topology optimization was run on the design space and the new geometry was formed.

-

Objective: Maximum stiffness

-

Material: Plastic (ABS)

-

Mass Targets: 30% total design space reduction

-The Polynurb tool was used to create a smooth geometry before printing.

Altair Inspire was used to topologically optimize the design space producing an organic, hollow, truss-like structure.

Combined Lattice and Topological Optimization